1. Aplication:

This type is used for drawing and annealing copper wire and other alloy wire from 2.6-3mm to 0.4-2.0mm.

2-Parameters:

| Machine type |

JC-17DHT |

JC-13DHT |

| Control system |

PLC |

PLC |

| Inverter control |

Two inverters control |

Two inverters control |

| Drawing dies No./max. |

17 |

13 |

| Inlet diameter |

Ø 2.6- 3.0mm |

Ø 2.6- 3.0mm |

| Out diameter |

Ø0.4- 1.6mm |

Ø0.65- 1.6mm |

| Drawing line speed /max |

2000m/min |

2000m/min |

| Slip ratio of m/c |

20% |

20% |

| Fix speed capstan slip ratio |

15.5% |

15.5% |

| Frame |

Ironed cast |

Ironed cast |

| Capstan |

Carbon fibre plasma capstan |

| Main motor |

55kw |

55kw |

| Spooler motor |

11kw |

11kw |

| Fix speed capstan dia. |

Ø 250mm |

Ø 250mm |

| |

|

|

| Online annealing |

250T/B |

250T |

| Wire range |

0.4-2.0 |

0.4-1.6 |

| Annealing voltage |

0-60V |

0-60V |

| Annealing current |

2000A |

1200-1500A |

| Spool bobbin size |

Ø 500mm -630mm |

| Optional take-up machine |

1-Drop coiler 2-Annealing part 3-Dual-spool take-up |

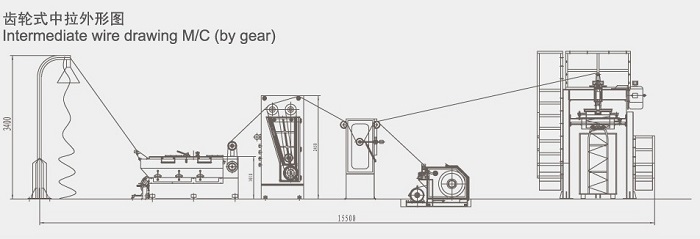

3-Scope of supply(as below photo)

4-Overview

Intermediate Wire Drawing Machine with Online Annealing

5-Advantage:

1). Special seal system between the gear box and drawing section to prevent oil leakage and mixed.

2). Ironed cast and Wear-resistant capstan can keep long life.

3).For Second-section-annealing system, outside electrically neutral (no current flow to other unit)

4). Longer annealing section with tension ensure good and stable elongation.

5). Two types annealing were available to meet different size range and raw material.

6).Besides normal copper, also is a good choice for brass and some welding wire.

6-Delivery time: 45-60 working days

7-After-sell service:

Engineer will be dispatched at needed.

The buyer provides engineer’s roundtrip flight tickets, board and lodging, the security as well as each person of daily wage.

8-Gurantee: 12 months since shipping date(exclude easily wearing part)